In today's rapidly developing digital industrial field, industrial switches play a crucial role. They are like "transportation hubs" in industrial networks, ensuring efficient and stable transmission of data information. Next, let's delve into the 7 core features of industrial switches together.

high reliability

Industrial environments are often harsh, facing many unfavorable factors such as large temperature changes, high humidity, high dust, and possible electromagnetic interference. Industrial switches have excellent high reliability, adopting a sturdy and durable shell design that can effectively prevent dust, water, and earthquake, and can operate stably even in complex and harsh industrial sites. At the same time, many industrial switches are also equipped with redundant power supplies, redundant links, and other functions. When one of the power supplies or links fails, it can quickly switch to the backup part, minimizing network interruption time and ensuring the continuity of industrial production is not affected. For example, the average time between failures (MTBF) of some industrial switches is ≥ 100000 hours, providing strong support for the long-term stable operation of industrial networks.

Wide temperature working range

Ordinary switches can usually only operate normally in relatively mild temperature environments, but industrial switches are very different. It can adapt to an extremely wide temperature range, generally from -40 ℃ to 85 ℃, and even some switches can operate normally under extreme temperature conditions of -40 ℃ to 75 ℃. Whether in cold environments of tens of degrees below zero, such as outdoor industrial project sites in high-altitude regions, or in extremely hot environments such as workshops near high-temperature production equipment, industrial switches can operate normally, providing a solid temperature adaptability guarantee for the stable operation of industrial networks, without problems such as crashes or performance degradation due to extreme temperature changes.

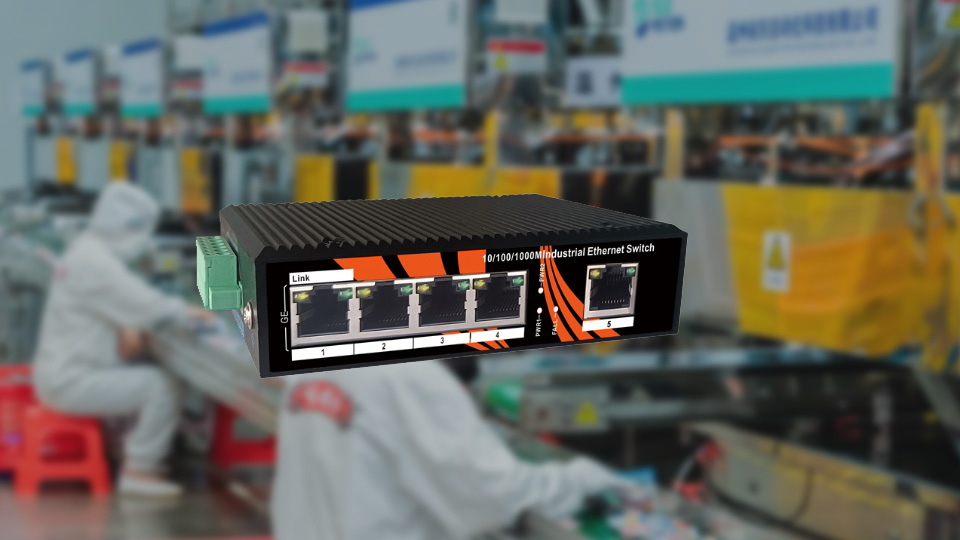

Flexible port density

Industrial switches have great flexibility in port configuration, providing multiple port density options according to the actual needs of different industrial scenarios. Common types include 8-port, 12 port, 24 port, 28 port, etc. From a small number of ports to meet the networking needs of simple devices, to a large number of ports to cope with complex industrial network topologies, such as the connection needs of numerous production equipment, monitoring equipment, etc. in large factories, they can all be achieved through suitable industrial switches. Moreover, the port types are also very rich, covering Ethernet ports, optical fiber ports, etc., to facilitate docking with equipment with different transmission media and build a fully functional industrial communication network. For example, the Huawei 25720I-SI series switches offer models with 8 Ethernet 10/100/1000 Base-T ports and 4 10G SFP+ports, as well as 24 Ethernet 10/100/1000 Base-T ports and 4 10G SFP+ports, to meet the needs of different users.

Strong anti-interference ability

There are various sources of electromagnetic interference in industrial environments, such as electromagnetic noise generated by large electrical equipment such as motors and frequency converters during operation, which can easily interfere with network signals. Industrial switches, with their excellent circuit design and shielding technology, can effectively resist these electromagnetic interferences, ensuring the accuracy and integrity of data transmission. The electromagnetic compatibility (EMC) of general industrial Ethernet switches is above level 3, which can ensure that the bit error rate of data transmission is ≤ 10 ⁻¹ ² in harsh electromagnetic environments, so that instructions, monitoring data and other information transmitted through the switch can arrive at the destination accurately and without error, thereby ensuring that the industrial production process proceeds in an orderly manner according to the established plan.

Fast redundant switching

In order to cope with possible network failures, industrial switches have a fast redundant switching mechanism. When the main link fails, it can switch data traffic to the backup link in a very short time, usually in milliseconds. For example, Jiffy Ring industrial Ethernet instantaneous ring redundancy technology can enable businesses to achieve self-healing within 18ms; The self-healing time of SOC DIP series industrial Ethernet switches is less than 20 milliseconds. This fast switching speed makes it almost impossible for devices in industrial networks to detect network fluctuations, thus avoiding production delays, equipment abnormalities, and other situations caused by network interruptions.

High security performance

Data security in industrial networks is crucial, involving critical information such as production processes and trade secrets. Industrial switches provide rich security features, such as access control lists (ACLs), which can restrict access permissions for specific devices; Port security mechanism can prevent illegal devices from accessing the network; There is also VLAN partitioning function, which divides devices with different departments and functions into different virtual LANs to achieve isolated data transmission, prevent internal data leakage and external network attacks. At the same time, industrial switches support port authentication using protocols such as 802.1X, and encrypt traffic using encryption protocols such as HTTPS and SSL. In case of abnormal situations, they also have firewall functionality, which can monitor and block potential attacks in real time. For example, some industrial switches support 4k VLANs, which can finely divide the network and improve network security.

Easy to manage and maintain

For industrial enterprises, equipment management and maintenance costs are also important considerations. Industrial switches have convenient management and maintenance features. They support multiple remote management methods, such as through web interfaces, command-line interfaces, or specialized network management software. Engineers can easily configure, monitor, and troubleshoot industrial switches distributed throughout the central control room or remote office locations. At the same time, it also has a comprehensive logging function, which can record important information such as device operation status and network connection status, making it convenient for management personnel to discover potential problems in a timely manner and make targeted solutions, greatly improving the efficiency of industrial network operation and maintenance. For example, the TL-SG2008 industrial grade switch of TP-LINK supports cloud management functions, which can remotely view device status, abnormal alarms, and troubleshoot. It also supports port monitoring, which can collect traffic information from various ports for easy monitoring of traffic and analysis of network anomalies.

In summary, industrial switches play an irreplaceable role in the industrial field with these 7 core characteristics, becoming the top choice for many industrial enterprises to build efficient, stable, and secure industrial networks. Whether it is the upgrading and transformation of traditional manufacturing industries or the network construction of emerging industrial projects, industrial switches will help the industry move towards a more intelligent and efficient direction with their excellent performance.