In today's era of rapid digital development, network communication equipment plays a crucial role, and switches, as a key part of it, are divided into different types such as ordinary switches and industrial switches. In some special industrial scenarios and extreme environments, industrial switches have shown unique advantages. Let's take a closer look at the characteristics of industrial switches and their advantages compared to ordinary switches.

1、 What is an industrial switch

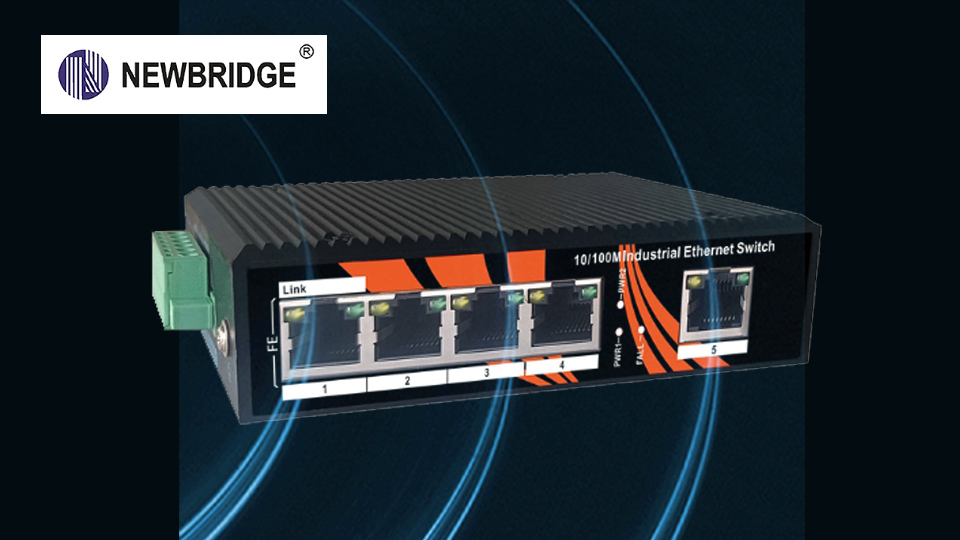

Industrial switches, in simple terms, are switches designed specifically to meet the application needs of industrial environments. It is usually applied in industrial fields such as factory workshops, mines, transportation hubs, and power systems, which often have complex and harsh environmental conditions and strict requirements for the stability and reliability of network equipment. Industrial switches are designed to ensure efficient and stable data exchange and transmission in various complex industrial conditions, ensuring the smooth operation of the entire industrial network system.

2、 Characteristics of industrial switches

1. Wide temperature working range

Industrial switches have strong temperature adaptability and can operate normally in extreme temperature environments. The normal operating temperature range of ordinary switches is relatively narrow, possibly around 0 ℃ to 40 ℃, while industrial switches can often operate stably in a temperature range of -40 ℃ to 75 ℃ or even wider. For example, in cold northern winter outdoor industrial sites or hot southern summer high temperature factory workshops, industrial switches will not malfunction due to temperature issues, always ensuring smooth network communication, which is one of its important characteristics in dealing with extreme environments.

2. High protection level

The shell design of industrial switches is more robust and has a higher level of protection, with common protection levels such as IP40, IP67, etc. The number after the IP represents the ability to prevent dust and water, which means that industrial switches can effectively resist the intrusion of dust, water vapor, and other substances. Industrial switches, with their excellent protective performance, can avoid damage to internal electronic components and maintain normal communication functions in places such as mines, dusty environments, or ports and docks that are easily affected by water splashes and humidity. However, ordinary switches are prone to faults such as short circuits due to dust accumulation or water ingress in such environments.

3. Redundant design and high reliability

In order to cope with unexpected situations that may occur in industrial environments, such as power fluctuations, network link failures, etc., industrial switches usually have built-in redundant power modules. When one power supply has a problem, another power supply can immediately take over the work, ensuring that the equipment runs without power. At the same time, there is also redundancy design in the network links, supporting functions such as ring network redundancy. Once a link fails, it can quickly switch to the backup link to ensure uninterrupted data transmission. Most ordinary switches lack such a comprehensive redundancy mechanism, which makes them more prone to network interruptions and other issues in the face of unexpected situations, affecting the stability of the entire network system.

4. Good anti-interference ability

There are often a large number of motors, large mechanical equipment, etc. in industrial environments, which can generate strong electromagnetic interference. Industrial switches adopt special circuit design and shielding materials, which have excellent anti electromagnetic interference capabilities. They can accurately transmit and receive data in strong electromagnetic interference environments without data loss, transmission errors, and other phenomena. Compared to conventional switches, in industrial environments with complex electromagnetic conditions, the accuracy and stability of data transmission will be greatly reduced.

3、 The advantages of industrial switches compared to ordinary switches

1. Stability advantage

The design of industrial switches, from hardware to software, is built around the high stability requirements of industrial environments. Under the requirement of long-term continuous operation, ordinary switches may frequently malfunction due to factors such as temperature, dust, electromagnetic interference, etc., requiring continuous maintenance and replacement of equipment. On the other hand, industrial switches, with their many characteristics of adapting to extreme environments, can operate stably for a long time, greatly reducing the risk of network paralysis caused by equipment failures and ensuring the continuity of industrial production and other activities.

2. Lifespan advantage

Due to the use of high-quality components and more durable casings in industrial switches, their overall lifespan is much longer than ordinary switches. In harsh industrial environments, ordinary switches may experience various performance degradation or even scrapping after one or two years of use, while industrial switches can maintain good operating conditions for 5 years or even longer. In the long run, they can better meet the requirements of the industrial field for the continuous use of network equipment and reduce the cost of equipment replacement.

3. Applicability advantages

Ordinary switches are more suitable for office environments with relatively good indoor conditions, suitable temperature and humidity, and low electromagnetic interference. Industrial switches can be widely used in various extreme industrial environments, whether it is high temperature, low temperature, humidity, high dust, or strong electromagnetic interference. There are corresponding models and configurations that can meet the corresponding needs. Therefore, in terms of application coverage in the industrial field, industrial switches have unparalleled advantages.

4、 Specific cases of industrial switches responding to extreme environments

Case 1: Offshore Wind Farm

The Phase II project of Guodian Xiangshan 1 # offshore wind farm is located in the southeast sea area of Shipu Town, Xiangshan County. The offshore wind farm has a large temperature difference between day and night, extreme high and low temperatures, humid and salt spray marine environment, vibration of wind turbine units, and harsh electromagnetic environment of wind turbine control systems. AOBO series industrial Ethernet switches are applied in the wind turbine SCADA communication network system, wind farm wireless network coverage system, video surveillance network system, etc. in this project. This series of switches adopts industrial grade high-quality device selection, a sturdy fanless alloy shell design, shock resistance, drop resistance, vibration resistance, and corrosion resistance. It has been verified by authoritative institutions' electromagnetic inspection and testing, and has excellent electromagnetic compatibility (EMC level 4), surge protection, and a working temperature of -40 ℃ to 85 ℃. The switches adopt "three protections" treatment, fully meeting the application requirements of extreme harsh environments in offshore wind farms. At the same time, the solution adopts a more reliable A/B physical dual ring guarantee, integrates the unique MABRing multi link redundant ring network technology, has a more flexible networking method, and a more reliable communication network, ensuring the long-term stable operation of various monitoring systems in offshore wind farms.

Case 2: Subway Communication System

The Changsha Metro Line 6 passes through "five districts and one county", with a total length of 48.11 kilometers and 34 stations. The machine room of subway stations often faces challenges such as vibration caused by vehicle operation, metal dust, poor ventilation, and large annual temperature ranges. New H3C Group provided industrial switches for the signal system of Changsha Metro Line 6, including the deployment of IE4320 rack mounted industrial switches in the central part of the ground signal system "Five Ring Network", and the use of strong earthquake resistant full M12 interface IE4300 industrial switches on vehicles. All components of the New H3C industrial switch are made of industrial grade products. The fanless metal casing can achieve passive heat dissipation, with a maximum working temperature of 75 ℃. At the same time, the fanless design also gives the product a higher IP protection level. The IE4300 has reached the IP67 protection level, which can completely prevent the invasion of dust and moisture. All interfaces of IE4300 use M12/M16 connectors to ensure stable and reliable physical connection of ports in harsh environments with strong vehicle vibrations. At the same time, the device supports two bypass ports, which can ensure the connection of front and rear devices even if the device loses power, comprehensively avoiding network interruptions and improving network reliability.

Case 3: Rolling mill workshop of steel plant

The environment in the rolling mill workshop of a certain steel plant is high in humidity and temperature, and there is electromagnetic interference and vibration. After deploying the optimized industrial switch and running continuously for 12 months in a 95% humidity and 80 ℃ high temperature environment, the network availability increased from 83% to 99.98%. This industrial switch is strengthened through hardware, using a fully metal shell and sealed structure to enhance impact resistance, dust and water resistance. It is equipped with industrial grade wide temperature components (-40 ℃~85 ℃), combined with active heat dissipation design, increasing power module redundancy, and supporting dual 24V DC or PoE++power supply. At the same time, through protocol optimization and utilizing the adaptive mechanism of industrial Ethernet protocol, link switching can be completed within 50ms to ensure real-time communication. Traffic shaping technology is introduced to compress network latency from 150ms to within 20ms. These measures effectively enhance the stability of industrial switches in harsh environments and ensure network communication in the rolling mill workshop of steel plants.

In short, industrial switches, with their unique characteristics and significant advantages compared to ordinary switches, have become a powerful assistant for ensuring industrial network communication in extreme environments. With the continuous improvement of industrial automation and intelligence, the importance of industrial switches will become increasingly prominent. In the future, they will continue to play a key role in the industrial field, helping industrial production and operation to be more efficient and stable.